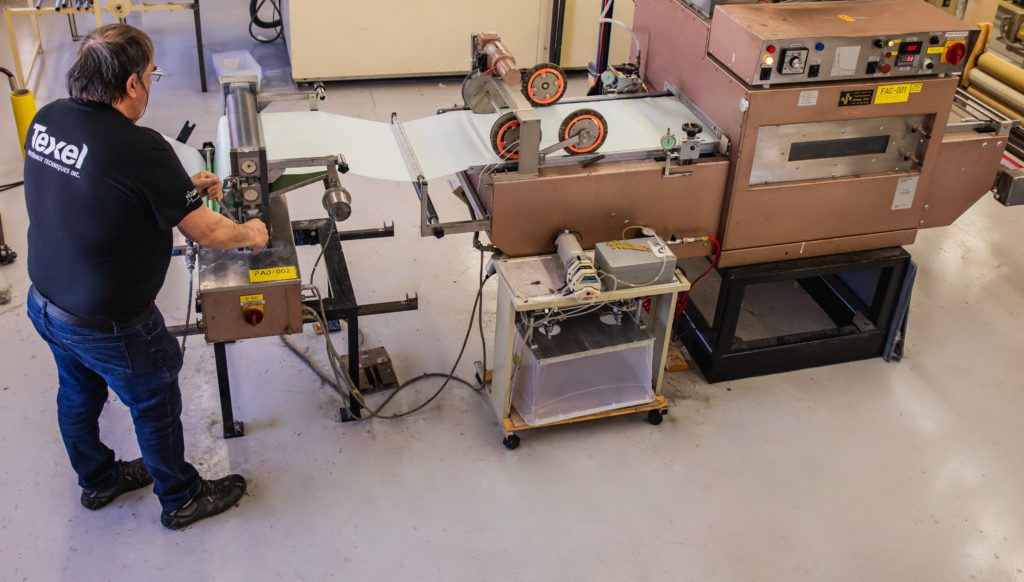

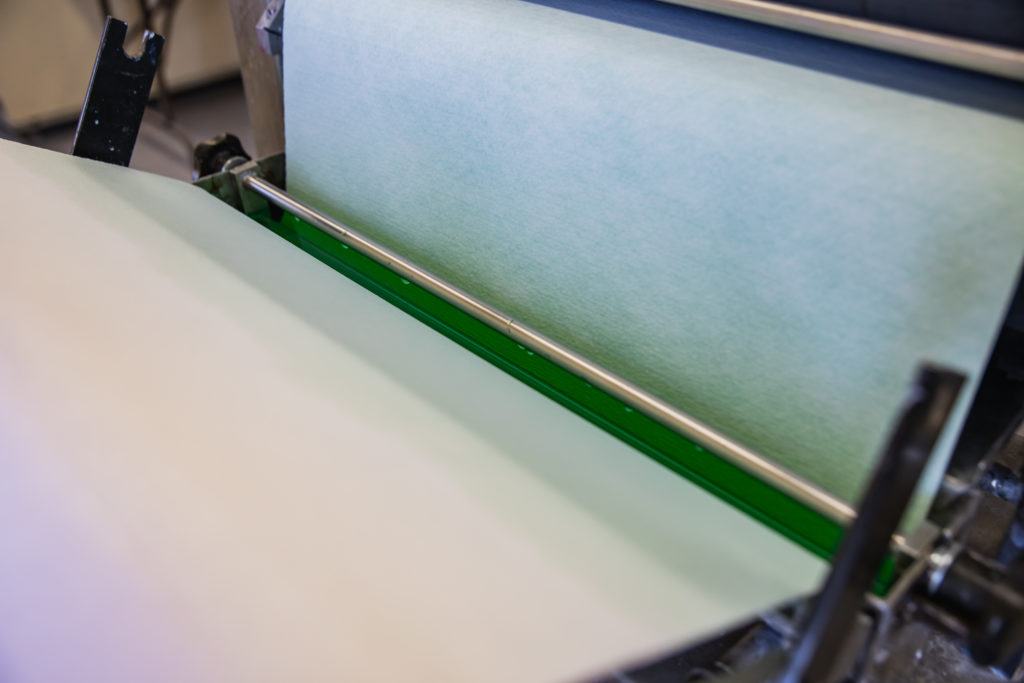

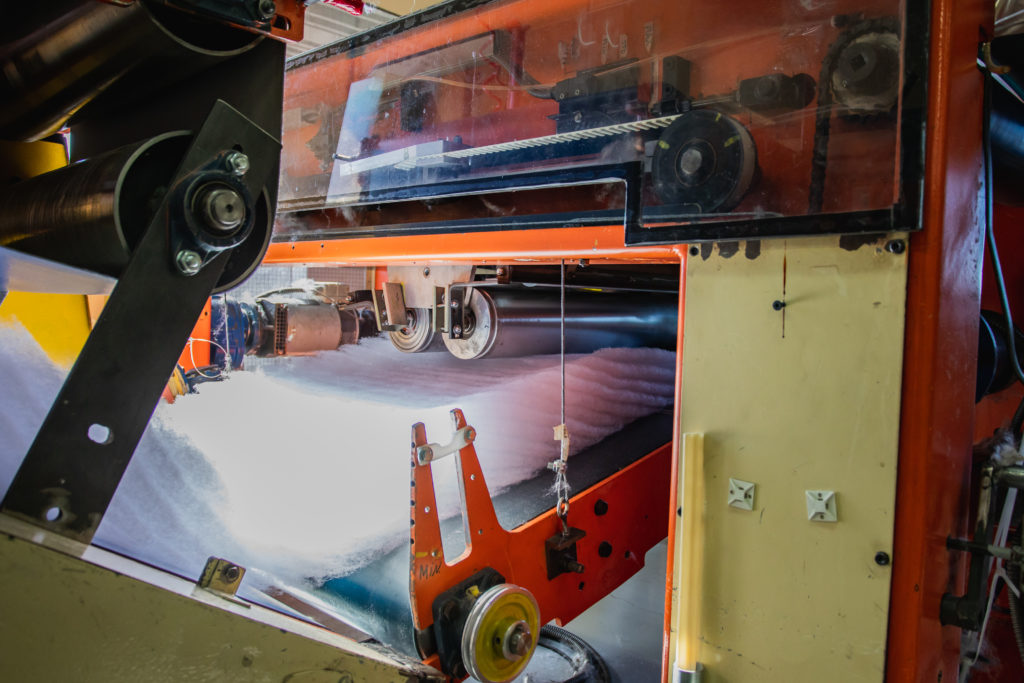

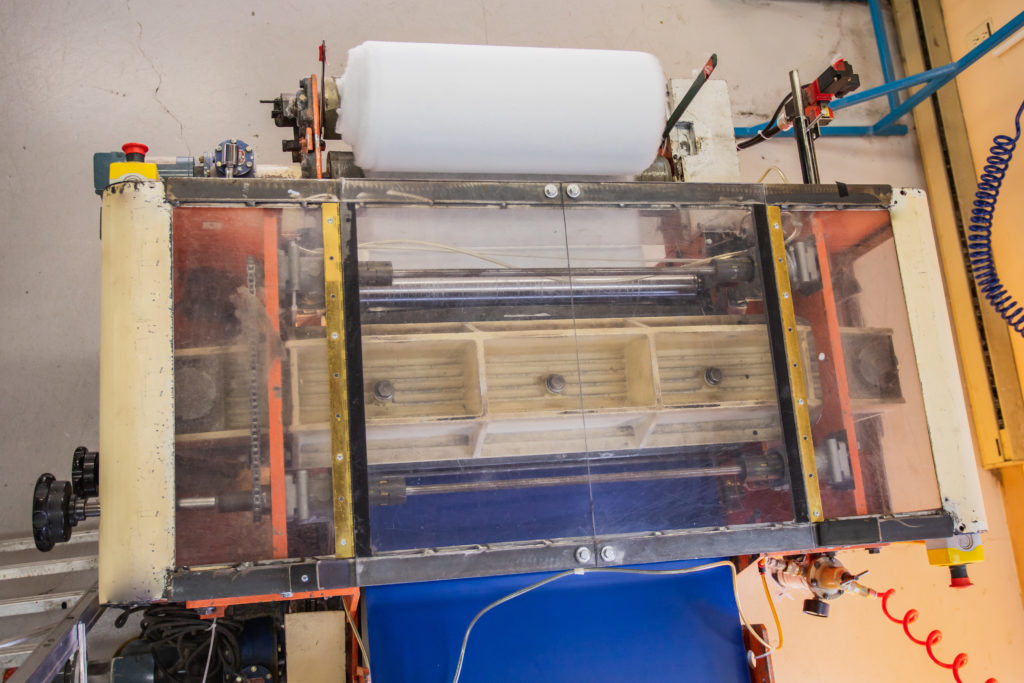

Texel Technical Materials Inc. is recognized as an innovative company. Texel has one of the few prototypes needlepunch lines in North America, which reliably reproduces the production process of needlepunch nonwovens. Our prototypes can be produced in one or more iterations for testing purposes to: (in part)

• Validate the choice of fibers during the design of the nonwoven (choices are made preferably with the help of the client and/or future users);

• Exchange or gain experience on a material concept or product design;

• Prepare data or various elements of an experimental design that are useful to validate hypotheses;

• Develop new fiber mixtures (natural, synthetic, aramid or other);

• Design a new product, equipment or structures, required for a new process;

• Test the reactions of future users or consumers;

• Prepare technical specifications;

• Illustrate new concepts.

Our rapid prototyping service makes it possible to quickly bring ideas to life, and thus validate the relevance of certain choices more efficiently and quickly. With this process, we were able to develop our Düotex 6.3mm and 12mm, and thus create our color palette of the Feltkütur acoustic panels collection.

Our lab has a small-scale needlepunch nonwoven line, a coating impregnation oven system, a heated calendar system, a flame treatment system (lamination or surface treatment singeing), a surface treatment by infra-red and a continuous belt compression lamination and heat-bonding process.

Thanks to its prototyping laboratory, Texel technical Materials inc. is an innovation hub for needlepunch non-woven manufacturing in North America, not to mention its dedicated research and development team, composed of technicians, researchers and project managers. A know-how that is perpetuated and constantly evolving.